What is EPERAN™?

EPERAN™ is a product name of polyolefin foam which Kaneka has uniquely developed with bead method and successfully commercialized for the first time in the world. Our product of EPERAN™PP- polypropylene foam, and EPERAN™ -polyethylene foam supports people’s lives in a variety of Food/Housing scene with its energy absorption and light weight property.

EPERAN™PP (Bead method Polypropylene foam)

|

Its excellent properties of heat resistance and dimensional stability enable to be applied in a wide variety of industries, from the bumper shock-absorber to the tool-boxes in the automobile parts industry, and protective packaging material in the electric-part and precision instrument industry, and many. |

|

EPERAN™PP |

|

| Product Information > |

EPERAN™ (Bead method Polyethylene foam)

|

In the extent of its elastic unbreakable property, it is widely used as protective packaging material and distribution industry material. |

| EPERAN™-XL™ Protective packaging material | |

| EPERAN™-AXL™ Antistatic grade | |

| Product Information > | |

Properties

EPERAN™PP and EPERAN™ can be easily made designed into complex shapes using established steam chest molding techniques.

| Shape molding | Multi-impact | Energy absorption | ||

|

|

|

||

|

EPERAN™PP and EPERAN™ can be easily made designed into complex shapes using established steam chest molding techniques. |

When subjected to impact shock, as a result of being dropped, or to vibration in transit, EPERAN™PP and EPERAN™ can easily absorb stress and will not break or deform in normal use. |

EPERAN™PP and EPERAN™ have outstanding cushioning and energy absorption properties and can therefore offer excellent solutions in the field of safety and protection for the automotive and other industries. |

| Flexibility and resilience | Structural strength | Durability | ||

|

|

|

||

|

EPERAN™PP and EPERAN™ demonstrate outstanding elasticity and strain recovery properties, allowing the foam parts to return to their original shape even after severe bending or compression. |

EPERAN™PP and EPERAN™ have high load characteristics and strength, high temperature resistance and excellent creep characteristics, even at low densities. |

EPERAN™PP and EPERAN™ have excellent impact strength, strain recovery and flexibility. Furthermore they have superior resistance to UV radiation, abrasion and other physical and environmental wear and tear. |

| Lightweight | Buoyancy | Thermal properties | ||

|

|

|

||

|

Due to their outstanding cushioning properties, EPERAN™PP and EPERAN™ can provide outstanding results with a minimum of volume and weight, thus being more cost effective to transport, store or in overall weight reduction. |

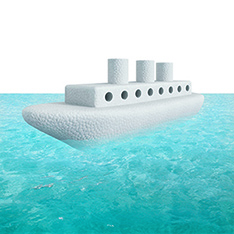

Thanks to the closed-cell structure, EPERAN™PP and EPERAN™ have a superior long-term floatation capability, and they are not affected by lengthy exposure to either fresh or salt water. |

Being closed-cell foams, EPERAN™PP and EPERAN™ have effective insulation properties and thermo-stability. In the recently developed specialty products the thermal insulation were boosted to a superior level. |

| Flame retardancy | Chemical resistance | Multi-grade molding | ||

|

|

|

||

|

Although the flame retardant properties of standard EPERAN™PP and EPERAN™ are limited, the non-halogen flame retardant grades dispose of self-extinguishing properties in both horizontal and vertical burning conditions. And in case of a fire, the heat release rate is low and the generated smoke is non-toxic. |

EPERAN™PP and EPERAN™ show little or even no degradation when exposed to various oils and chemicals and have excellent weather and moisture resistance. |

Kaneka has developed a very cost-effective patented technology allowing the molding of multiple grades in one and the same part, in order to meet specific requirements for the automotive and returnable container businesses. |

| Recyclability | ||||

|

||||

|

EPERAN™PP and EPERAN™ consist solely of easily recyclable polypropylene and polyethylene. |

|